VAF Def-Aero Systems Private Limited co-develops components with the customer to suit the end application

At VAF Def-Aero Systems Private Limited, we have the infrastructure and expertise to design and develop aluminium castings of the most challenging complexities. With trained and qualified personnel with considerable expertise in Pattern Tool And Development, we offer the finest Pattern Tool And Development services in the industry.

Process Design Review / APQP

The design team studies the 2D and 3D information provided by the customer to check for the manufacturing compatibility. Any required design changes are carried out with concurrence from the customer

Tool design and simulation

The team uses scientific calculations and concepts derived from experience to design the best possible method for producing the part. This is confirmed with the use of simulation softwares. We also carry out non destructive testing Liquid Penetrant Testing, liquid penetrant inspection, Dye Penetrant test.

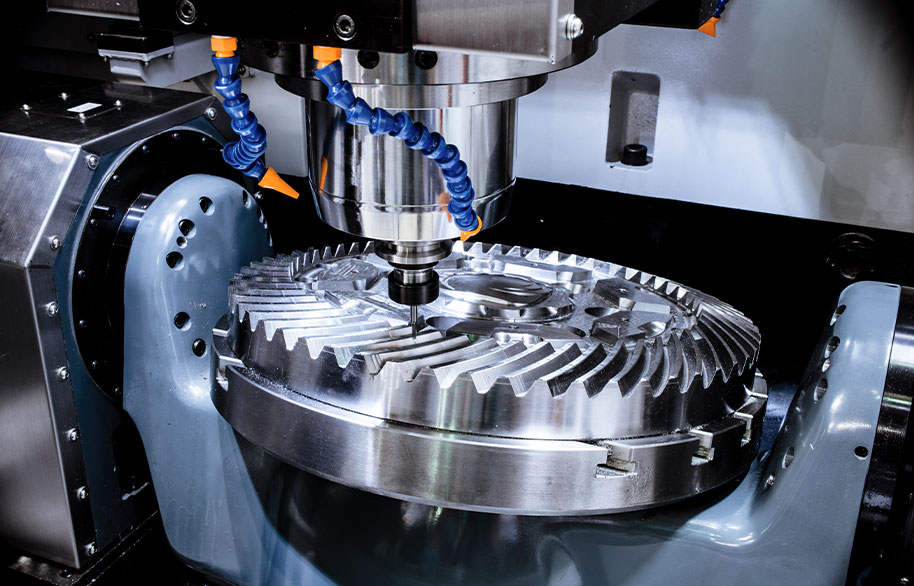

Manufacturing

Manufacturing Being a premium casting industry in india With complete inhouse capabilities for machining, testing and fabrication, the development team can manufacture dies, patterns and machining fixtures with quick turnaround times.

Sampling and testing

Manufacturing Being a premium casting industry in india With complete inhouse capabilities for machining, testing and fabrication, the development team can manufacture dies, patterns and machining fixtures with quick turnaround times.

Fit for Production

With approvals from customer and the production department, the part will be certified as Fit for Production and handed over to production.