Facilities of quality control sysytem

Quality Policy

As the manufacturing world is moving from PPM to "Zero Defect", At VAF Def-Aero Systems Private Limited, we are committed to providing our customers complete quality satisfaction through automated process controls and the benefits of sustained improvements.

Quality Objectives

A strict regimen of checks and inspections managed by a highly trained staff in our Quality Assurance Department ensures that all our products comply with established norms and regulations. From procuring raw materials to analyzing finished products, every stage of manufacturing processes is subject to rigorous quality checks.

Testing Facilities

The hallmark of any quality assurance program is the infrastructure available for conducting testing of components and products at various stages of production. We have facilities for undertaking a variety of test such as

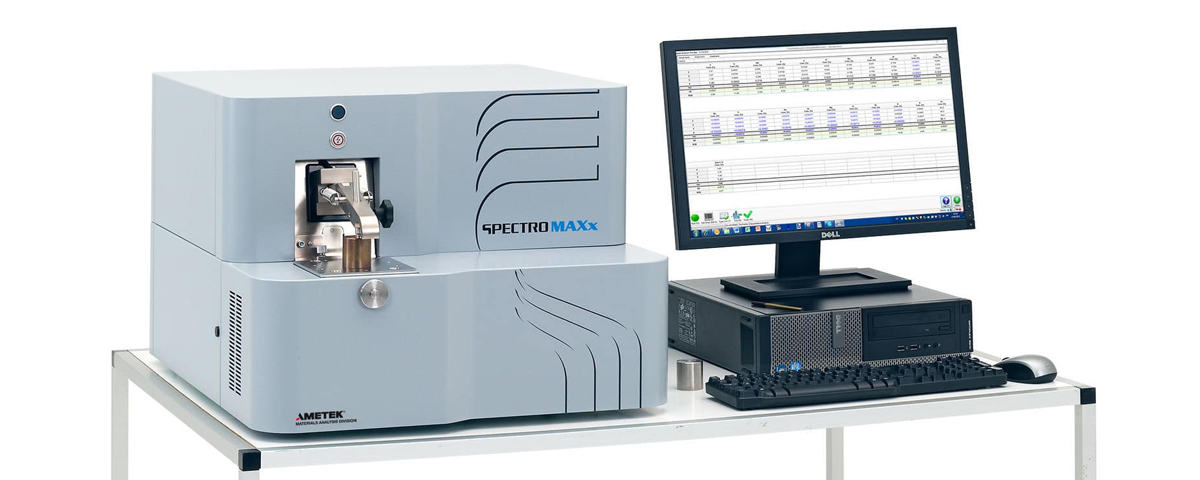

Spectrometer

- Make: AMETEK SPECTROMAXx

- To quantify the chemical composition of raw material, molten metal etc.

- Can detect up to 29 elements with high accuracy, repeatability

- Unique “iCAL 2.0” one sample standardization helps maintain the same standardization, regardless of most temperature shifts

Metallurgical Microscope

- Make: Dewinter, Inverted microscope

- Magnification: 100X, 200X

- Camera: 5.0 megapixels with progressive scanning CMOS image sensor

- Capable of viewing and analyzing microstructure, to measure:

- Grain size as per ASTM E112/E1382-91

- Coating thickness as per ASTM B487

- Phase segmentation as per ASTM E562, E1245

- Dendritic Arm Spacing

Universal Testing Machine

- Make: FSA Universal TUE-C-200

- To measure mechanical properties like yield strength, ultimate tensile strength, %elongation etc.

- Capacity: 200 kN

- Least count: 10 N

- Accuracy: ± 1%

- A Microcontroller based data acquisition system for data acquisition & online indication

- The Win UTM software can run a variety of mechanical tests, recall data from previous test & prepare test report.

Coordinate Measuring Machine (CMM)

- At VAF Def-Aero Systems Private Limited, we have 2 CMMs that are bridge-type with precise probe systems that yield high measuring speed outputs, precise, stable and highly reproducible measurement results.

- ZEISS Contura CMM

- Size (mm): X-1200; Y-1800; Z-1000

- Software: Calypso 6.8

- Probe: PH10M/TP20 with VAST XXT 2.5 degree rotatable head

- Hexagon B&S Global Performance CMM:

- Size (mm): X-900; Y-1200; Z-800

- Software: PC-DMIS CAD2023 R2

- Probe: PH10M/TP20 with 5 degree rotatable head

Gloss meter

- Make: Kency GM-268

- To quantify the gloss levels of matt to mirror surface finishes

- Measuring Geometry : 20 / 60 / 85 degrees

- Range : 0.1 to 200 Gloss Units (GU)

- Accuracy : ±1.0 GU

- Resolution : 0.1 GU

- Repeat ability : ±0.5 GU

- Measuring Area : 7 x 14 mm (Ellipse)

- Data Memory : 254 Groups

Digital Coating thickness gauge

- Make: Kency

- To measure the thickness of anodized coating, painting, powder coating etc., on ferrous, non-ferrous surfaces

- The device is portable. Yields accurate, repeatable results and can be easily calibrated

| Hardness Testing | Leak Testing | Pressure Testing | NDT-Dye Penetrant Test |

| Sand Lab: Moisture Content Testing | Core Hardness Testing | Mould Hardness Testing | |

We carry our specialized procedures such as "Failure mode & effect analysis" to ensure high quality standards in our products . Every part that we manufacture is adequately documented through the quality management system, in the digital domain in order to ensure repeatability in production.

From the purchase of raw materials to the dispatch of finished parts, we maintain complete process control to ensure quality. Strict controls also ensure that products can be developed as per required standards with excellent reproducibility. Through sustained training programs, every employee is trained to understand and employ quality measures throughout the operational processes.